COB (Chip-on-Board) and SMD (Surface Mount Device) technologies are the top players in the LED display arena, exhibiting significant differences in processes, product performance, reliability, energy efficiency, and costs. This article delves into a thorough comparison of these two packaging technologies, providing insights into their distinctions from various angles.

Crafting Techniques Clash

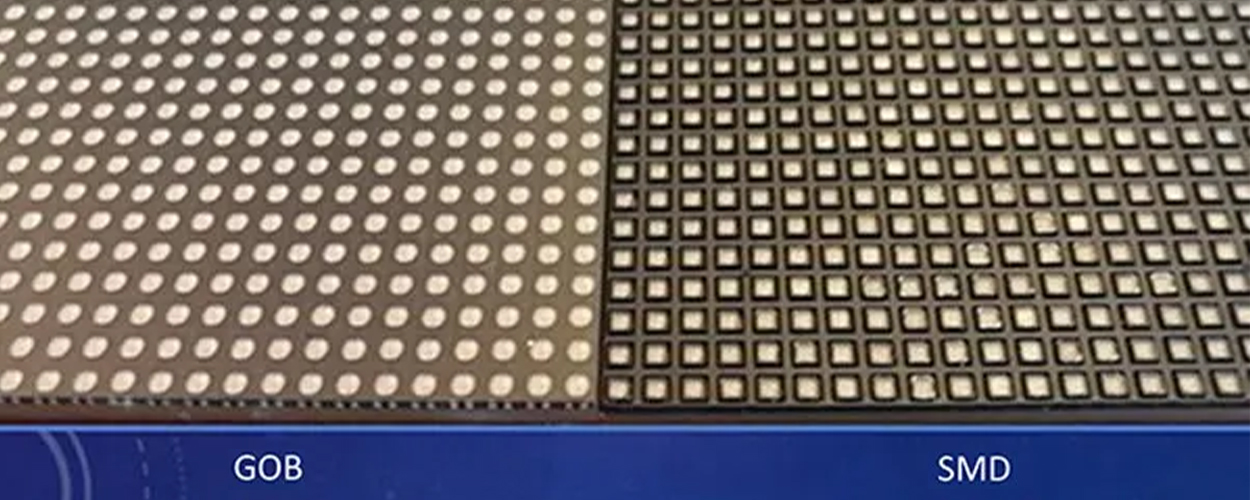

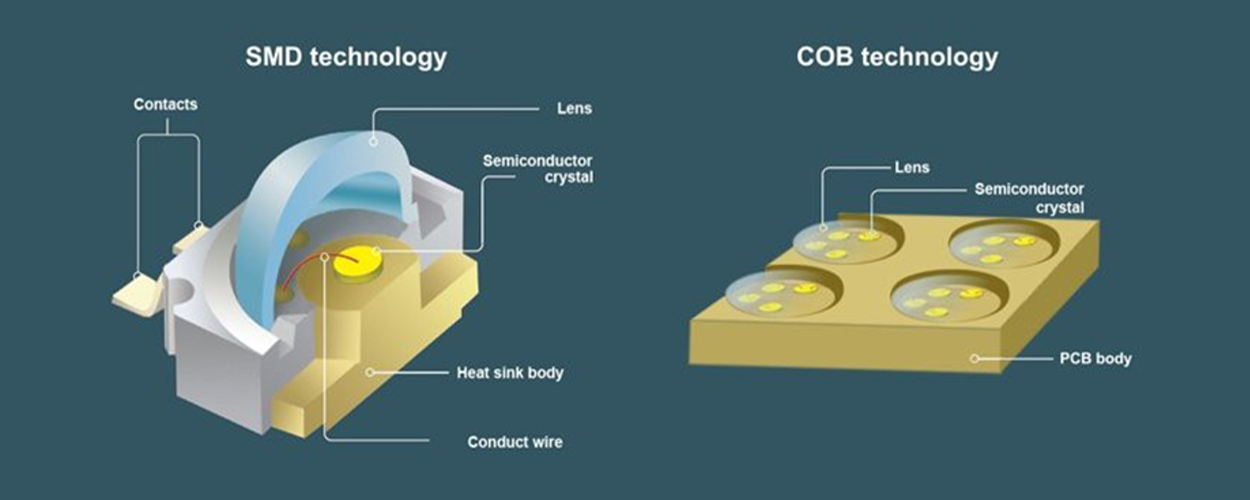

SMD Technology: Assembling LED chips into unit modules, creating a point light source effect.

COB Technology: Directly soldering LED chips onto PCB boards, encapsulating them with an overall coating to form unit modules, resulting in a surface light source effect.

Battle of Product Performances

Visual Disparities:

- SMD screens showcase a point light source, whereas COB screens use coating scattering and refraction to achieve a surface light source, offering superior visual aesthetics.

- COB screens boast higher contrast ratios, resembling LCD screens when viewed head-on, delivering richer colors and superior detail rendering.

Reliability Showdown:

- SMD screens generally have weaker overall protection but are easier to repair.

- COB screens offer enhanced protection, with a need for specialized equipment during repairs.

Energy Efficiency Duel:

- COB screens, employing inverted technology, exhibit lower power consumption, ensuring better economic feasibility.

- SMD screens, with most chips utilizing forward technology, tend to have relatively higher power consumption.

Costly Confrontation:

- SMD technology involves complex production processes, but due to its low technical entry barriers, there are numerous manufacturers nationwide, resulting in fierce competition.

- COB technology boasts lower theoretical costs, but due to lower product yield, it currently faces a cost disadvantage compared to SMD screens.

Conclusion

In summary, COB technology excels in image performance, reliability, and energy efficiency, but it faces some disadvantages in terms of cost and ease of repair. The choice between COB and SMD technologies depends on specific application scenarios and requirements. Whether you’re pursuing superior image quality or considering long-term cost-effectiveness, gaining a deep understanding of the disparities between COB and SMD technologies will aid in making informed decisions.

Post time: Nov-28-2023